PVD or Physical Vapour Deposition is a process in which a solid material is vapourised in a vacuum chamber and deposited, atom by atom, onto an item to form a thin layer that changes the item’s finish. This deposition also penetrates the surface, improving finish adhesion and durability. PVD can also be more environmentally friendly than electroplating and powder coating as it doesn’t typically produce the chemical waste associated with these processes. This process can impart the chemical properties and surface finish of a donor metal, e.g. copper, onto the recipient material.

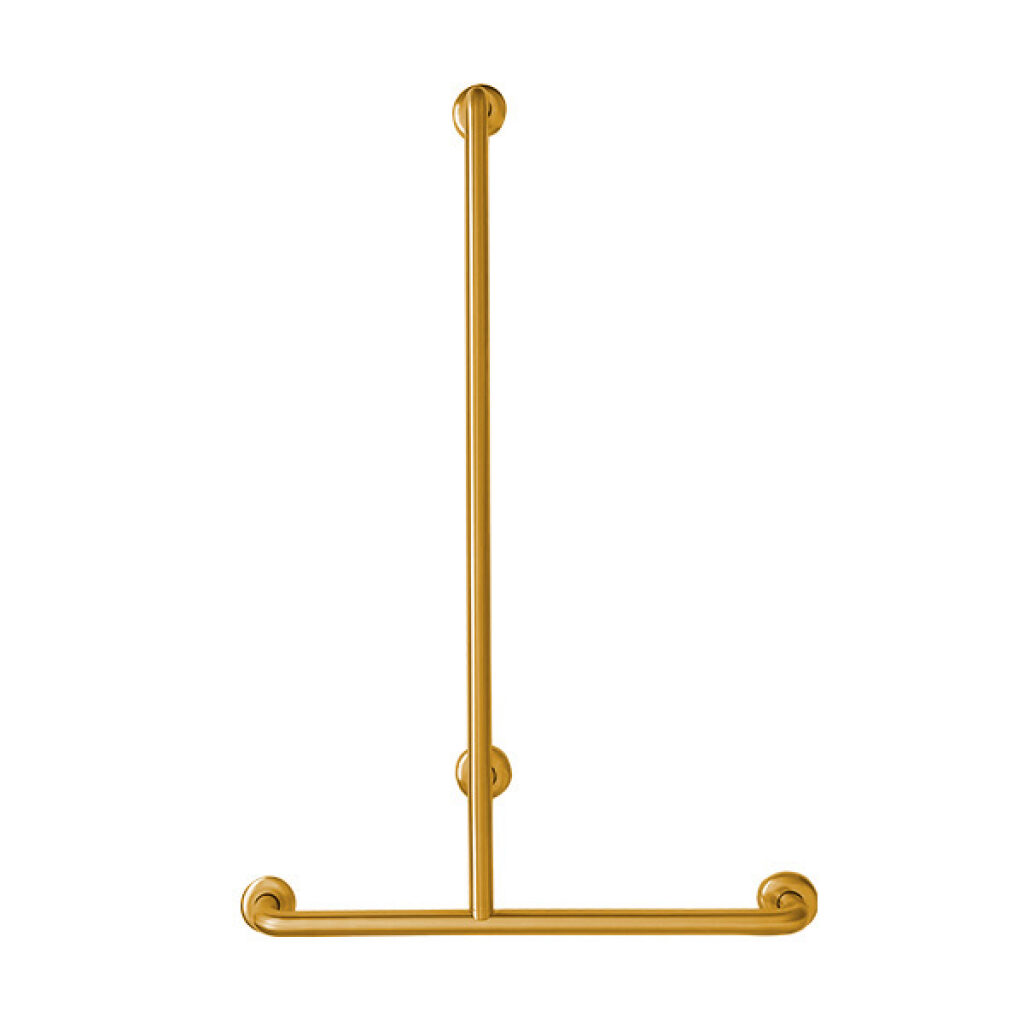

Available in brushed brass or gunmetal, RBA’s new range of metallic PVD grab rails is sure to suit any upscale commercial project. Contact us today for more info!